Which will make it more pertinent and relevant to the engine that is being built! Photographs and reference to a previously built engine is an unacceptable and poor shortcut, not enough photographs from differing angles of what you should be working towards!Ī proper set of accurate working drawings on either paper or CD would make an incredible difference.Facebook Tweet Pin LinkedIn Email Print Yummly Lamppost Engine

#Steam tractor plans update#

Please make significant amendments and update this book. To meet requirements of two means of delivering water to the boiler. The mechanical water pump should run all the time, if the engine is idling water is being boiled away. Also heating becomes trickier with more copper to hear up. The boiler build details are now outdated, flanged end plates are required and the boiler tube needs a thicker wall, this will cause fixing problems when the engine is assembled towards the end of the build. I have also started the steel work first, the cheapest option in case things go awry.īe prepared to practice your skills of you are a beginner, I am not in this category and have had to do a lot of head scratching. This is definitely not for the fainthearted, I have spent a lot of time reading and redrawing the components to make details as clear as possible.

Building jigs to assist making will add lots of hours. The time scale is also elastic, expect it to take far longer. At the time of writing the three cock water gauge is over £100.00.

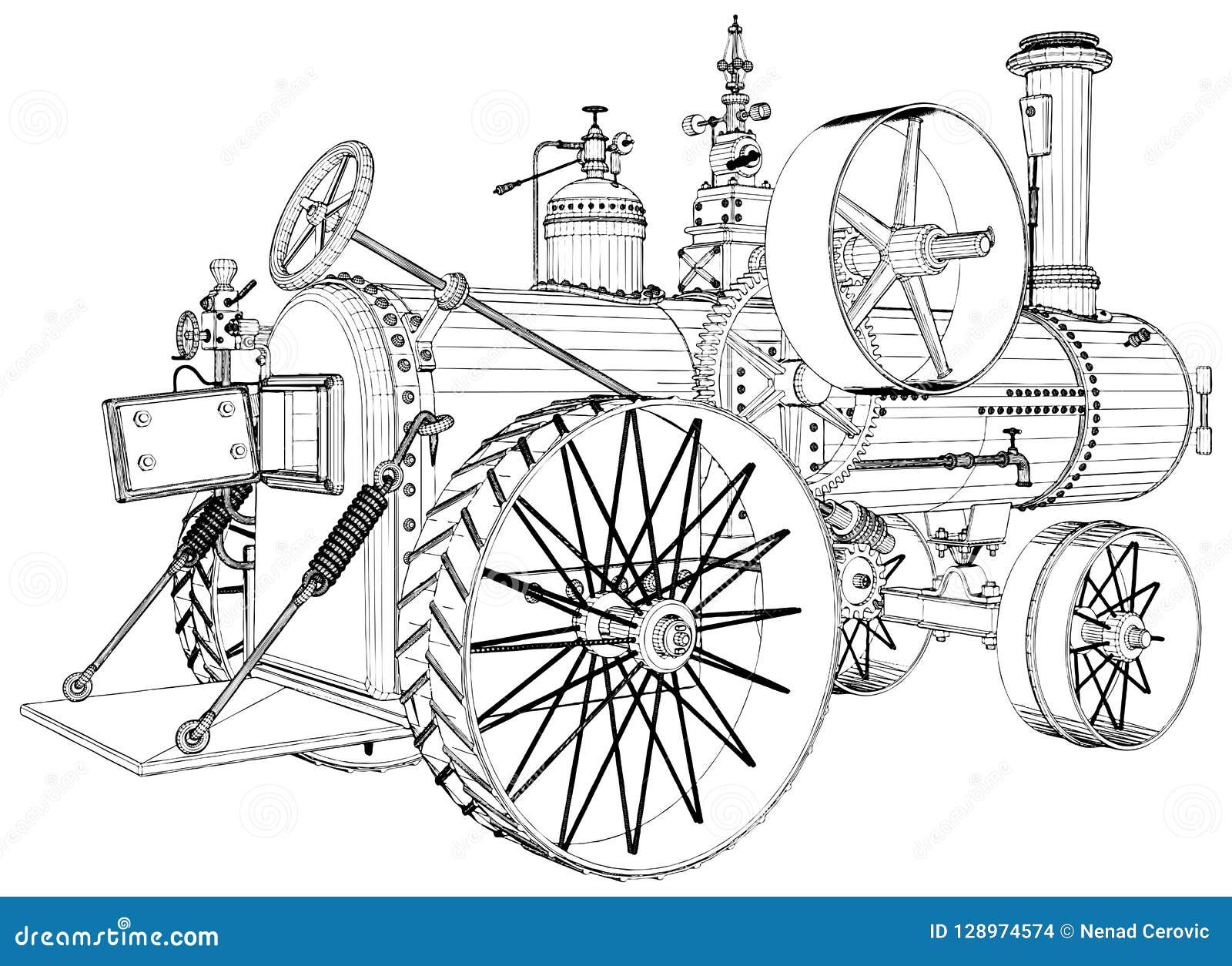

Having researched further, this engine is certainly cheaper than a fully geared one, the cost of standard components will ramp the cost up quickly. Too many references to a previously built engine, and on going assumption that the reader can get by. There are no page numbers or chapter headings, I had to post stick the chapters This is most certainly not novice level lathework. Take care, chunks of steel or brass rotating in chucks with small jaws may simply fly out. Some of the lathe work will require considerable thought, especially if a hobby lathe is used. Get someone to do it properly on a vertical mill!! I strongly advise anyone not to mill out the steam chest using a drilling machine, this is not safe. I advise careful checking here,too late when the material has been cut This could cause considerable difficulty and additional expense. Copious written detail could have been avoided with larger and clearly dimensioned drawings, and correct conversion from imperial to metric sizes ( there are lots of these errors). No conformation to conventional drawing standards have been used. The diagram quality is poor in places and some duplicated diagrams have different sizes. I do not consider that this book is easy to understand or suitable for a beginner,especially when there are considerable errors throughout. This is an upgraded version covering the latest steam regulations By looking at this you’ve taken the first step to owning your own live-steam traction engine and with just a little persistence it will not be long before you are driving your own live-steam creation, built with your own hands being pulled around easily as you watch the crankshaft and flywheel spinning almost silently right in front of your eyes as you trundle along. Many have been built already by amateurs, proving the simplicity of design and being completed quickly compared to similar sized but more complicated engines and only two parts need to be purchased to complete this engine, other than steam fittings, the heating and transmission, making this engine an inexpensive project to complete with most being readily available stock from most hobby shops. She's 26 inches long and weighs around 60lbs when ready for steaming and pulls an adult round with ease. Needs mostly hand tools, with a small amount of very simple lathe usage. Many photos from the build along with drawings to make your life easier.

#Steam tractor plans how to#

A First-timer's full instruction guide showing how to build a genuine, steam-powered Pull You Round Traction Engine named PYRTE.

0 kommentar(er)

0 kommentar(er)